Vertical space can not be fully exploited as shelves in traditional manual warehouses are low, while the flat space requires a large land area but the space utilization is low, resulting in a small amount of stored goods;Manual picking and storing results slow information updates and undesired labor efficiency;;Warehouses are greatly affected by the environment and cannot be used artificially in dark, low temperature, toxic and other environments. The labor-intensive working environment is greatly affected by COVID-19, and it is difficult to overcome the shortage of personnel.

The R&D team of ZS Robotics has been working in the field of intelligent warehousing for10years, and it is committed to create more durable, more stable and more adaptable four-way shuttle robots as well as its supporting products and software systems for customers. Getto knowsix advantages of four-way shuttle robotsdeveloped byZS Robotics.

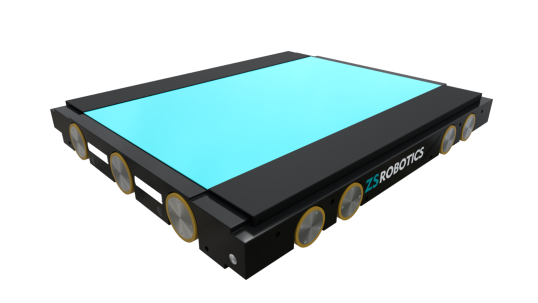

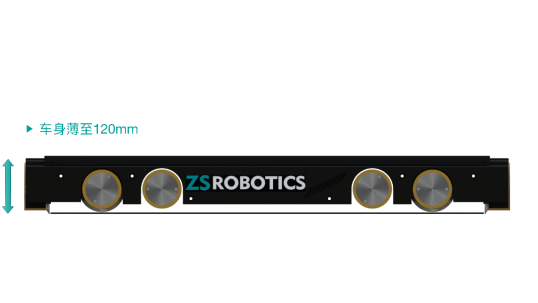

1) Smaller and thinner body in this industrywith a dead weight of merely275kg and a carrying capacity up to1300㎏.Suitable for various materials/pallet structures with lower cost on shelves;

2) Innovative, efficient and purely mechanical structures with higher carrying capacity and better equipment stability;Climbing speed up to2.5s because of patented structure;Stable and durable structures with a failure rate of< 0.01%;No liquid fat of the equipment; Environment-friendly and no risk of contamination.

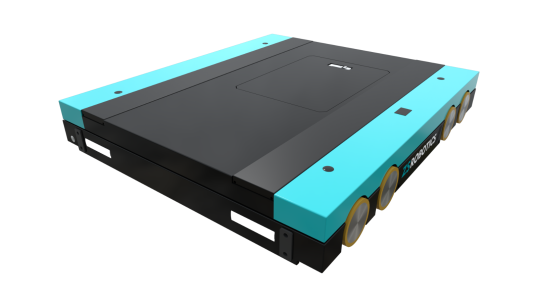

3) Modular plug-in design: Overall modularity rate >90%with electronic controlled plug-in design and highly integrated structure to achieve easy maintenance

4) Move stably with all-wheels: With multiple wheel groups and all-wheel drive design, it can move stably and prevent sliding with stronger road grabbing; It can span gaps in any directions and is suitable for more complex warehouse environments.

5) Stable mechanical structure with longer life and longer battery life due to high-capacity 40AH battery.

6) Fast implementation through self-learning: Equipment can learn the operation map independently; Repair and calibrate the positioning point automatically; And remove dust from the positioning code automatically;New vehicle deployment can be finished in 1 hour with lower implementation cost

![[Intensive, Efficient, Flexible] ZS Robotics Warehouse Solution [Intensive, Efficient, Flexible] ZS Robotics Warehouse Solution](/public/upload/20230822/230R2132305541.png)

No. 31011502019351

No. 31011502019351